Company: British Steel (formerly TATA)

Location: Scunthorpe

Duration: 15 Years

BRITISH STEEL MAINTENANCE CONTRACT

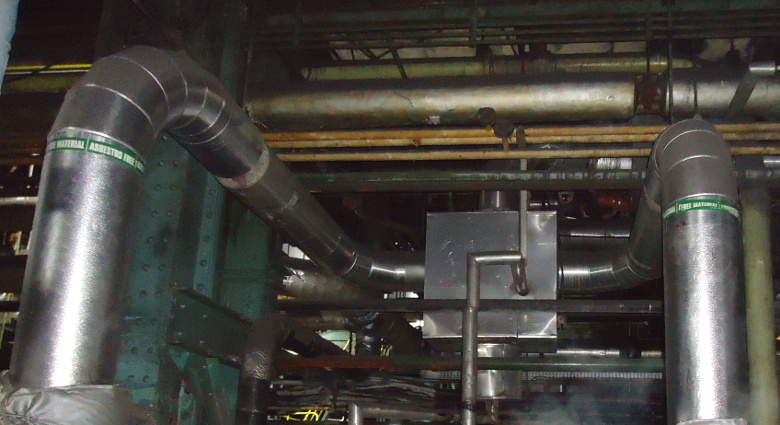

Rilmac provide a full time based maintenance insulation team on the British Steel Scunthorpe site, comprising of two to three Thermal Insulation Engineers. The main activity is the removal of existing insulation in either of the two steam raising power stations and the replacement of the insulation on completion of mechanical maintenance of the equipment. The type of work is mainly boiler header pipework, vessels and turbine steam chests. This maintenance team are also used across the site in the ironmaking, steelmaking and rolling mills.

Feedback From British Steel:

Why did you require thermal insulation?

“Within the two power stations steam is raised to a maximum of 480°c so thermal efficiency and safety are the main reasons. Elsewhere frost protection, thermal efficiency and safety are the main priorities for insulation.”

Can you please write a short statement on our performance in dealing with your enquiry?

“The contract is placed for a period of two years, with the option of extending, depending on agreements in the contract value. During the negotiations for the contract, Rilmac provide a comprehensive scope of work and schedule of rates, which we are more than happy to meet and discuss, with prompt in replies to any queries raised.”

How you feel that our onsite team performed their work?

“The onsite Thermal Insulation Engineers are well experienced in working on the British Steel Scunthorpe site and are mostly self-managed. The work order is passed to them via a British Steel contract owner engineer and for the most part they contact the requesting area, agree the scope of work, measure, order material, provide a basic risk assessment/method statement and submit a day work sheet for approval at the end of the work. The response out of hours working is mainly met by the onsite team or provided for by other resources by the management team. The Rilmac management team meet on a weekly basis with British Steel engineers and regularly attend the monthly departmental safety meeting. Rilmac demonstrate a high level of flexibility and can react to most situations as they arise.”

How do you, as the customer benefit, from our works?

“The contract provides a service of insulation removal and refitting that runs parallel to the maintenance activities on the site. For most parts this is well managed with few interruptions to plant operations.”

Request a Quote

Contact Numbers

Rilmac Insulation - Lincoln

Crofton Drive, Allenby Road Industrial Estate, Lincoln, Lincolnshire LN3 4NJ

Tel: 01522 781437

Fax: 01522 510291

Rilmac Insulation - London

5 Cecil Court, Pegrams Road, Harlow, CM18 7QR

Tel: 0800 612 9002

Rilmac Insulation - Leicester

Unit 2 No. 5 Knights Close Thurmaston Leicester LE4 8EW

Tel: 0800 612 9002

Rilmac Insulation - Manchester

Unit 27 Caldershaw Centre, Rochdale, OL12 7LQ

Tel: 0800 612 9002

Rilmac Insulation - Nottingham

Stapleford Road Trowell Nottingham NG9 3RP United Kingdom

Rilmac Insulation - Huddersfield

Heritage Exchange, Wellington Mills, Plover Road, Lindley, Huddersfield, HD3 3HR

Tel: 0800 612 9002

Rilmac Holdings LTD

Crofton Drive, Allenby Road Industrial Estate, Lincoln, Lincolnshire LN3 4NJ

Tel: 01522 531711

Fax: 01522 510291

What Our Clients Say

"Thanks very much for your involvement in helping us come to a satisfactory outcome.

Firstly meeting me on site at short notice and then coming to an arrangement to allow operatives to repair the pipe in a safe environment.

The feedback we got from the tenant and our operatives re your operatives work was first class."